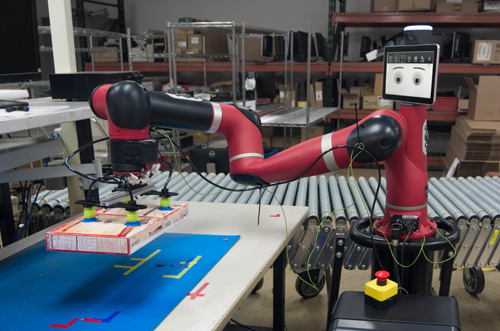

DHL is piloting two test robots in its warehouses. Named Baxter and Sawyer, they are able to work on a number of tasks relating to “value-added” services (those beyond DHL’s core of parcel delivery), including assembly and packaging.

Up until now, the advance of robotics in logistics has been limited due to the complexity of operations. “Historically, the distribution environment has been difficult to automate using traditional industrial robots, which do not respond well to variability,” explains Matthias Heutger, Senior Vice President of Strategy, Marketing and Innovation at DHL.

However, Baxter and Sawyer, from Rethink Robotics, are able to do monotonous tasks, such as line loading, machine tending and material handling, in an adaptable way. They are able to respond to the environment and “learn” from human staff rather than needing to be programmed for every task, receiving continual software updates.

Baxter was Rethink Robotics’ first, pioneering model, while follow-up Sawyer is more suited to high speed and high precision tasks. Both of them are strange, long-limbed creatures with tablet-like screens for heads and a pair of cartoon eyes.

The robots are collaborative, which means they work alongside humans. However, they are likely to win any staring contests.

(Sources: Deutsche Post DHL Group, Rethink Robotics)

On social media? Why not give us a follow...