3D printing presents a huge threat to the supply chain industry, according to the CEO of Transport Intelligence, John Manners-Bell. Transport Intelligence is a market research company.

Trade has gone increasingly global over recent years, with manufacturing made cheaper by using remote, low-cost locations and cheap labour. But according to Manners-Bell, the instant, on-demand nature of 3D printing may mean a reversion to regionalised trade as it negates these advantages.

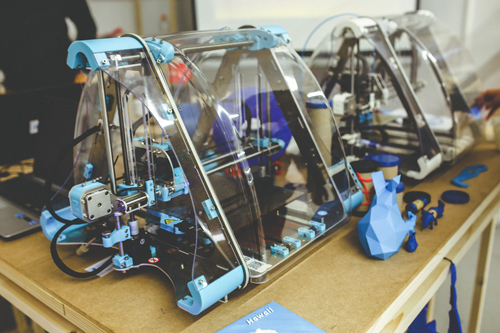

3D printing, he says, coupled with the evolution of robotics, will allow for inexpensive manufacturing in Europe and North America, and as such many manufacturing industries will not always require the same globalised network or supply chain.

The potential effect this has on the logistics industry means that carriers and forwarders would be making a huge mistake in ignoring the advances of 3D printing. “Some lines say it’s niche, and it won’t have an effect,” says Manners-Bell. “I don’t think that’s the correct assessment of the threat.”

Automotive and spare parts logistics companies, for example, face reduced volumes as 3D printing reduces the need for their transportation services. Any businesses that rely on supply chain “disruption”—that is, those that have identified and exploited a need for greater efficiency or convenience in the existing supply chain—face a threat from this emerging technology.

Elsewhere in the cargo industry, 3D printing has already had an unexpected impact: thieves are breaking into shipping containers by using 3D scanners and printers to create counterfeit security keys.

On social media? Why not give us a follow...